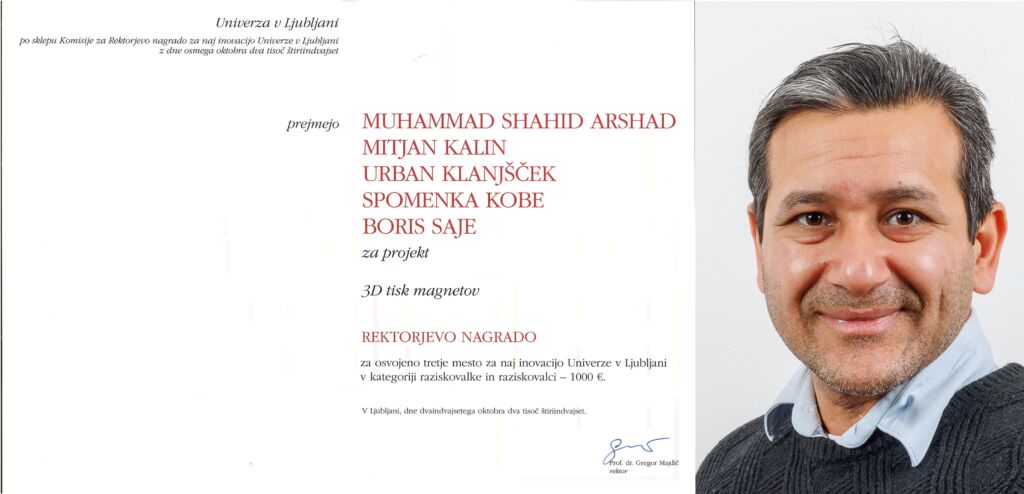

In partnership with the Faculty of Engineering, University of Ljubljana, we were awarded the third Rector’s Award for the patent as a final result of the EIT Manufacturing project aProMag.

The main objective of the project was to prototype, validate and bring to market a technology for rapid prototyping of rotors for brushless DC motors and actuators using 3D printing in a magnetic field that enables anisotropic alignment of hard magnetic material. The advanced technology reduces waste through 3D printing technology, with very low waste and material used reusable up to 5 times (~97% material yield). Advanced technology reduces waste through 3D printing technology. The source of feedstock powder is raw material recovered from end-of-life NdFeB magnets, enabling a circular economy. The technology also significantly reduces the time to produce end products to test design concepts by up to 5 times and significantly reduces the cost of conventional injection moulding tooling. The end user to test the new methods is KOLEKTOR, a world-renowned manufacturer in the field. The technology is patented.