Consolidation of rapidly solidified Nd-Fe-B magnetic powders

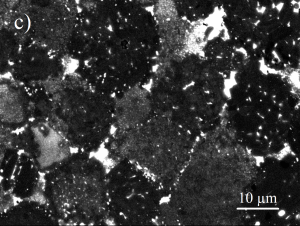

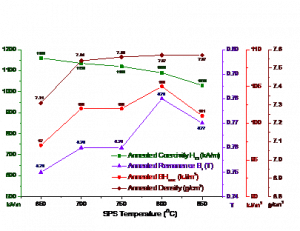

Nanostructured Nd-Fe-B magnetic powders, prepared by rapid solidification of the melt, have a unique microstructure not obtainable with conventional powder metallurgy. High resistance against external demagnetization fields can be achieved when the grain size is of the order of the single-domain.

This holds true even in the case of a material without any addition of the critical HRE elements. Densification of the fine-grained magnetic powder is a crucial step in the production of bulk magnets. To avoid grain coarsening during consolidation, short processing times and low temperatures are needed. For this purpose, our group uses pulsed electric current sintering (PECS), also called spark plasma sintering (SPS) technique. We prepared bulk nanostructured magnets with high intrinsic coercivities by carefully controlling the process parameters. In addition to the well-researched melt-spun ribbons, we prepared dense bulk permanent magnets from the spherical gas-atomized Nd-Fe-B powder with microstructural characteristics and magnetic properties similar to the starting material. PECS technique offers the possibility to produce magnets with complex shapes, a highly desirable feature for some applications. Since this type of magnets provide higher magnetic flux density than polymer-bonded magnets, they have a high potential to be used in a wide range of devices where strong magnetic field is needed.

Contact:

Ferrite-based hybrid magnets for energy storage applications

Permanent magnets are crucial in modern technology as they allow storing, delivering and converting energy. They are able to transform electrical energy into mechanical and vice versa, which means that improving their performance entails transforming energy in a more efficient and sustainable way.

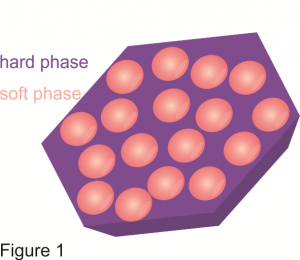

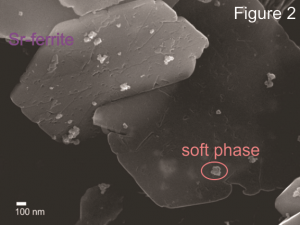

The energy density stored by a permanent magnet, defined by the maximum energy product (BHmax), is its figure of merit. The best permanent magnets are based on rare-earths (RE) and reach BHmax values between 200-400 kJ/m3. Permanent magnets made of ferrites and alnicos, the other two main families of magnetic materials, barely grasp 45 kJ/m3. Importantly, a number of key technologies rely on magnets with moderate energy products within the range 50-200 kJ/m3. An increase in the BHmax of ferrite-based magnets would open an entire new field of possible applications. First steps towards achievenig this goal were made by combining magnetic hard and soft phase in isotropic magnets. At the moment our group is focused on the preparation of ferrite-based hybrid anisotropic magnets with enhanced magnetic performance (BHmax > 50 kJ/m3), which would be installed in a flywheel (electric energy storage device).

Jenuš. P. et al: Ferrite-Based Exchange-Coupled Hard-Soft Magnets Fabricated by Spark Plasma Sintering, Journal of the American Ceramic Society, 2016 vol: 8 (37805)

Contact:

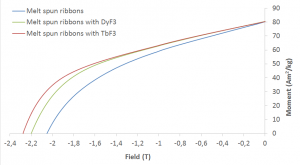

High-coercivity Nd-Fe-B permanent magnets with minimum amount of heavy rare earths

Nd-Fe-B permanent magnets play an important role in rapidly growing alternative energy devices (electric vehicles, hybrid electric vehicles and wind turbines). Such devices are able to exploit the largest maximum energy product (BHmax) among all other magnets. Unfortunately, there is still a room for improvement the coercivity, since magnets based on the Nd-Fe-B hard magnetic phase have a theoretical maximum coercivity in excess of 6000 kA/m. What limits Nd-Fe-B based magnets without Dy and Tb (HRE) to 1500 kA/m is their microstructure. One of the options for adding Dy or Tb into the Nd-Fe-B matrix phase is the blending technique. In this case usually 2 wt. % to 10 wt. % of Dy or Tb is added to improve the coercivity. Clever microstructural engineering was introduced to improve the coercivity, since Nd-Fe-B grains on nano-scale were used in this process. The dependence of the grains size on the coercivity is well known parameter and smaller grains provide greater coercivity due to the lack of the defects in the combination with smaller demagnetizing field. Using the grain-boundary diffusion process on melt-spun ribbons led to coercivity enhancement.

Contact:

Materials for a magnetic heat pump

The magnetocaloric effect (MCE) is a magneto-thermodynamic phenomenon and is defined as the heating or cooling of a magnetic material due to the application of a magnetic field.

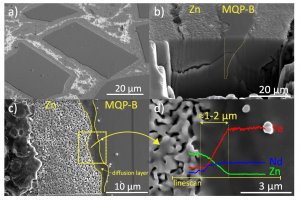

To improve the mechanical and thermal properties of the magnetocaloric material La(Si,Fe) used as a working material in a magnetic heat pump, we produced a composite by mixing La(Si,Fe) with Zn in a ratio from 10 to 40% in a pulsed electric curent sintering device. The produced composites showed a dense microstructure with a small drop in the magnetocaloric effect due to the dilution of the working material. With reasnoble thermal conductivity, needed to remove the heat from the hot source, we achived a suatible candidate to substitute the now used critical raw material Gadolinium. With the liquid phase of Zn we will be able to form the composite into complex structurtes which is crutial in forming a element with a high surface area and a high heat transfer. As a positive side effect Zn is damping the volume changes occuring in the La(Si.Fe) during phase changes, hindering its decomposition into powder.

Contact:

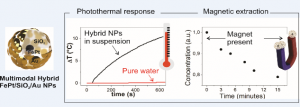

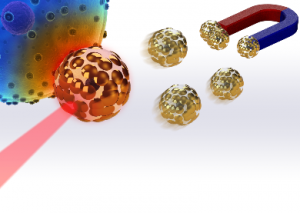

Multimodal hybrid FePt/SiO2/Au NPs

We are researching the possibility of using multi-functional/hybrid “nano-systems” that enable a targeted multifunctional diagnosis and therapy i.e. enabling the »theranostic« action. The proposed smart diagnostic, targeted drug delivery and stimuli-responsive release system is based on hybrid optically and magnetically active nanoparticles, which facilitate both, focused localization and extraction of hybrid FePt/SiO2/Au nanoparticles by using an external magnetic field, and photothermal treatment. The FePt nanoparticles were produced in a single and multicore version with improved magnetic properties. FePt/SiO2 NPs were further functionalized with biocompatible zwitterionic catechol ligands which introduce excellent hydrophilicity. FePt NPs were coated with SiO2 /Au and showed large absorption the range between 550 and 850 nm, which make them superior to commercially available Au NPs with a discrete absorption peak. The suspension of these FePt/SiO2/Au core-shell nanoparticles was irradiated with a laser at the wavelength λ = 810 nm at P = 1 W. The temperature increased with a rate of 2 K/min, which makes this material suitable for photo thermal cancer treatments.

Contact:

Spark plasma sitering of metal bonded Nd-Fe-B magnets

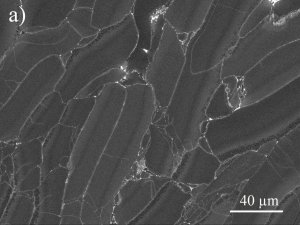

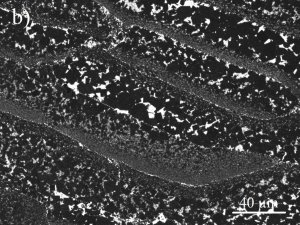

We developed a novel technique for producing metal-bonded Nd-Fe-B magnets by pulsed electric current sintering (PECS). Low melting point (LMP) metallic binder, which enables these magnets to be used at temperatures higher than 180°C, was used.

LMP-metalic bonded Nd-Fe-B composites have been demonstrated to be feasible by hot compaction using the PECS technique. Composites were obtained for different amounts and size ranges of melt-spun Nd-Fe-B powder, yielding different end properties. Optimal results were achieved with the addition of 10 wt% Zn binder and the use of ~250 μm Nd-Fe-B powder. This combination yields the highest density due to the most favorable stacking of the particles, which has a substantial impact on remanence. Metal-bonded Nd-Fe-B magnets could find use in high-temperature automotive applications.

Contact:

Magnets for electric motors used in Electric Vehicles and Wind Turbines

Advanced processing of high energy Nd-Fe-B magnets to decrease the amount of heavy rare earth and increase the magnetic performance.

During the rare-earth (RE) crisis in 2011, the rare-earth prices, especially the heavy rare-earth (HRE) were skyrocketing, e.g. price of terbium (Tb) jumped to 3000 €/kg. HRE are now on the very top of the world List of Critical Materials. The crisis caused a serious alarm among the producers and end-users of permanent magnets. The magnetic group developed a new innovative technology, which enabled the production of Nd-Fe-B magnets for motors used in electric cars and wind turbines with 16-times less amount of HRE for the same performance. This achievement, which places the Slovenian magnetic group among the world top research groups in the field, is a product of 25 years of basic and applied research in the field of intermetallic alloys between rare-earth and transmission metals. The new technology was recommended by industrial partners for eco-efficient production and brings a huge financial saving. Technology developed at Jožef Stefan Institute was implemented together with German colleagues to the pilot production in Vacuumschmelze, Hanau; 550 magnets were inbuilt in the two motor demonstrators: for an electric car of French producer Valeo, and wind turbine of German producer Siemens.

Contact:

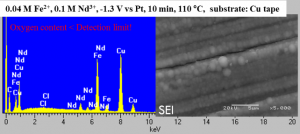

Electrodeposition of NdFe12-based thin film from ionic liquids

Efforts in finding a superior magnetic material to Nd2Fe14B have been ongoing since its discovery in the eighties. Current worldwide awareness of strategic importance of critical elements i.e. the rare earths (RE) and their reduction in permanent magnets triggered the research even more.

- We are investigating the the possibilities in electrodepositing RE-s (Nd) which is due to their large electronegative oxidation-reduction potentials (e.g. Nd3+(aq) + 3e– → Nd(s), –2.32V) very challenging together with transition metals like Fe, to form Nd-Fe alloys.

- The RE (Nd) and transition metal (Fe) are co-deposited from non-aqueous electrolytes with the emphasis on ionic liquids (called low-temperature molten salts have unique physicochemical properties, such as high ionic conductivity, a wide electrochemical window, low vapor pressure and high thermal stabilities), deep eutectic solvents and molten salts aiming at the metallic Nd-Fe deposit with tailorable RE content.

Projects MSCA-ITN-DEMETER

Contact:

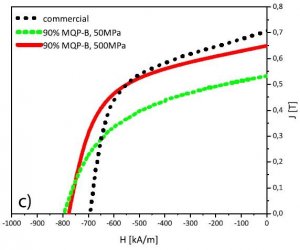

Development of Spark Plasma Sintered rare earth magnets (Nd-Fe-B & SmCo)

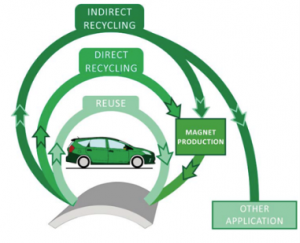

The ever-growing application spectrum of Nd-Fe-B permanent magnets (PMs) is challenged with the high process costs and wastages. Scrap magnets can be recycled and reused but with lower magnetic properties compared to the non-recycled ones.

- We are tackling the Nd-Fe-B (PMs) via direct recycling, in which case the magnets are treated as a raw material for the production of new magnets, via implementiong novel techniques of spark plasma sintering, to give new, ready-to-use, magnetic materials or a new master alloy that can be processed using existing magnet production facilities.

- Fully dense Nd-Fe-B and Sm-Co permanent magnets are prepared from the recycled alloys powders obtained via using spark plasma sintering, during which a pulsed DC current is directly passed through a graphite mould. Resistive heating plays a dominant role in the densification of powder compacts, achieving near theoretical density at lower sintering temperature compared to conventional sintering techniques. The heat generation is internal, in contrast to the conventional hot pressing, where the heat is provided by external heating elements. This facilitates fast heating rates (up to 300 °C/min). Process parameters are optimised in order to get the fully dense sample at the lowest possible temperature, where the grain-growth is negligible since smaller grain size gives better coercivity.

Project MSCA-ITN-DEMETER

Contact:

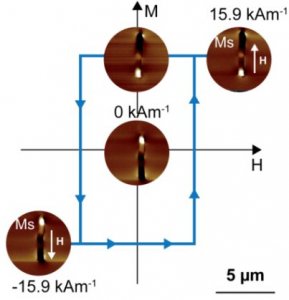

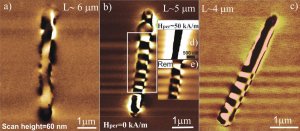

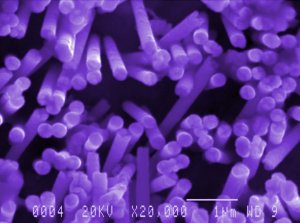

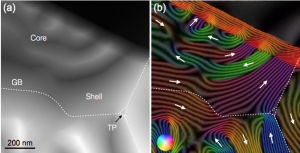

Electrodeposited nanowires and nanotubes for magnetic applications

Elongated magnetic nanostructures, nanowires (NWs) and nanotubes (NTs), have unique potential when talking about their applications either in magnetic storage and magnetic-based nano devices. Due to constrain on the nano level the magnetization can follow unique directions governed by the nanostructure crystal structure, size and shape. Magnetic force microscopy (MFM) on Fe-Pd NW revealed single-domain behaviour with the easy axis of magnetization along the long axis of the NW (Fig. 1), it was found that the dipolar interactions greatly reduce the remanence and the switching-field distribution of the Fe-Pd NW array. For Co80Pt20 hcp NWs the texturing of the direction [00] was observed that suggests the uniaxial anisotropy perpendicular to NW long axis that results in a unique periodic domain structure observed with MFM (Fig. 2). Such a type of domain pattern is the state with the lowest energy that can be applicable in the newest version of race track memory devices with perpendicular anisotropy. In fcc Co50Pt50 nanotubes the remanent state can be described with a vortex-type of closure exhibiting no stray field which has its origin in the minimization of the demagnetizing field that arises from shape and the surface or volume charges. Such NTs represent perfect candidates for magneto resistive random-access-memory devices and for biomedical applications.